Rumored Buzz on Sheroz Earthworks

Rumored Buzz on Sheroz Earthworks

Blog Article

The Greatest Guide To Sheroz Earthworks

Table of ContentsFascination About Sheroz EarthworksThe Single Strategy To Use For Sheroz EarthworksSheroz Earthworks - TruthsEverything about Sheroz EarthworksSome Ideas on Sheroz Earthworks You Need To Know

For any type of earthwork service provider, it is vital to carry out work with high quality, precision, and on routine. Making use of maker control in work makers enables enhancing the various stages in the earthwork procedure, from planning to the maintenance phase - topcon laser levels. The equipment control system helps the maker driver in obtaining the target aircraft rapidly and conveniently

The maker control system overviews the operator with centimeter precision. Remote assistance saves time and money, as it minimizes downtime in jobsites.

Sheroz Earthworks Fundamentals Explained

Our system's elements are meticulously created to hold up against the harsh problems of building sites. Comparison of the same job performed using maker control versus the typical approach exposes that, on standard, the typical approach needs 50% even more time to complete the very same job as the technology-assisted technique.

Enter the Xsite equipment control system; it's here to provide you with a significant advantage when working with earthmoving equipment. Discover exactly how Xsite Machine Control can boost your performance and guarantee work safety! Xsite Equipment Control systems can be set up to any type of excavator from mini excavators to big mining excavators.

How does equipment control job? In 2D systems, the machine is geared up with calibrated inclination sensors. These sensing units are installed on the pre-determined components of the machine in excavators the sensing unit are normally placed to the structure, boom (or booms), digger arm and to the quick coupler - fj dynamics auto steer price. By making use of the data obtained from these sensing units the system can determine the precise placement of the excavators bucket pointer in importance to a recommendation point.

The system is really easy to discover the essentials can be instructed in under one hour of training. Exactly how does the remote assistance job? A wireless net connection makes it possible to develop a remote connection between the maker control system and the service.

What Does Sheroz Earthworks Mean?

What type of information layouts Xsite systems assistance? Xsite Equipment Control systems sustain open typical data formats, allowing smooth details circulation from one system to another. Supported file formats: 2D-Maps: DXF Point documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Designs: DXF, XML What elements are mounted on my device? Depending upon your option of system (with or without positioning, i.e - fj dynamics auto steering kit price., 2D or 3D), your machine is outfitted with disposition sensors, a controller unit, and a display/operating panel.

Lots of software and hardware solutions exist to help establish a device's present position on visit our website the earth and contrast it with a desired layout surfaceand building drivers can do even more to leverage the benefits. Machine control is the use of numerous positioning sensing units and a display to give the operator with a recommendation between the placement of the bucket or blade and the target quality.

Relying on the setup, device control systems can provide the driver with an easy aesthetic guide to pail or blade position, or can automatically move the blade to quality by talking with the machine's hydraulics - https://www.magcloud.com/user/sherozau. There are machine control systems available for practically any kind of maker: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, milling makers, and pavers

The Best Guide To Sheroz Earthworks

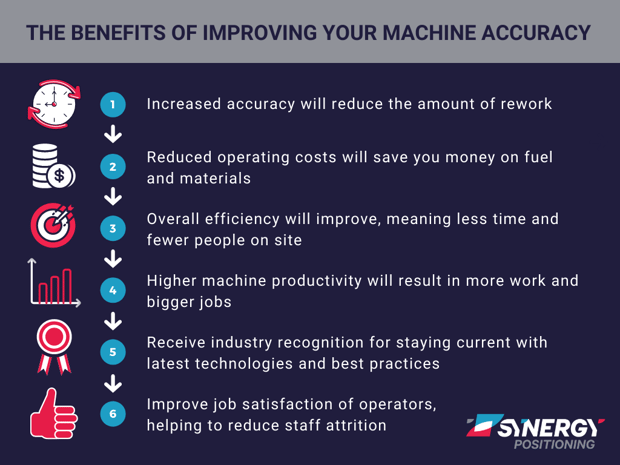

Some benefits include reduced rework, boosted job performance, and lower surveying costs. Equipment control can also aid boost performance and minimize overall expenses. This innovation is transforming the method the building and construction sector functions. Construction equipment without machine control will come to be a point of the past and the advantages acquired from it will be numerous.

Trimble equipment control systems give a myriad of benefits to anybody that makes use of earthwork equipment and, at EarthCalc, we can supply you with 3D declare your equipment control-enable devices. Not sure if equipment control deserves the cost? Take into consideration the adhering to reasons you need to consider this choice.

Making use of GPS straightened with your 3D style data, these systems practically guarantee that you will eliminate or put the right quantity of product at the building website. On many building websites, revamp is an usual and discouraging truth, but with Trimble equipment control, you can remove the requirement for rework.

More About Sheroz Earthworks

Usually, with Trimble maker control, you can get rid of excess devices at a details work website. For instance, a task that may have called for using three or 4 pieces of digging deep into tools now might require just two tools to complete the same job in much less time. This allows you to relocate your equipment to an additional job website and manage several tasks at one time.

Report this page